Introduction

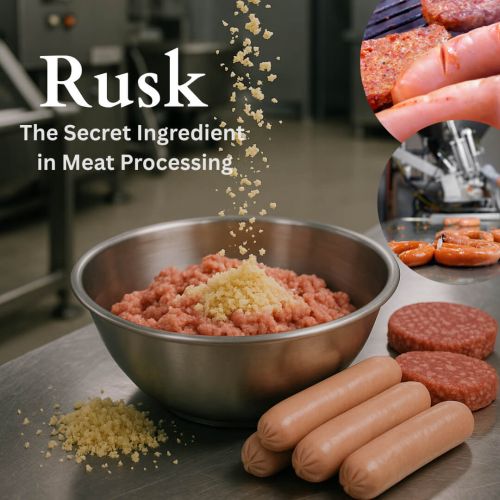

In the European meat industry, consistency, texture, and cost efficiency are key. One essential ingredient that helps processors achieve these goals is rusk. As a trusted solution in sausage making, burger production, and other processed meat applications, rusk plays a vital role in ensuring quality and performance.

If you are a meat manufacturer, foodservice supplier, or importer in Europe looking for reliable ingredients, understanding the benefits of rusk is crucial. Below are the top five uses of rusk in meat processing.

Rusk is widely used as a sausage binder and in burger formulations. It binds meat, fat, and water, creating a uniform structure that prevents crumbling during cooking. This makes it an essential ingredient for:

Pork and beef sausages

Meatballs and kebabs

Frozen and fresh burger patties

High-quality breadcrumbs for meat processing can absorb and retain moisture, ensuring that meat products remain juicy and tender after cooking. This not only improves taste and mouthfeel but also increases production yield—helping processors achieve better efficiency and profitability.

Texture is one of the most important quality markers in meat products. Rusk provides a firm, consistent bite while preventing shrinkage during cooking. It ensures even distribution of fat and seasoning, resulting in a premium texture that appeals to consumers across Europe.

With its neutral taste, rusk acts as a perfect carrier for herbs, spices, and seasonings. This ensures even flavor distribution throughout the product. From traditional sausages to innovative meat formulations, rusk helps maintain flavor balance in every bite.

Rusk allows processors to partially replace meat while maintaining product integrity, texture, and flavor. This makes it a cost-effective solution for manufacturers looking to remain competitive in the European meat processing market without sacrificing quality.

Conclusion

At Agrocannedfoods, we specialize in manufacturing and exporting high-quality rusk and breadcrumbs for meat processing. Our products comply with international standards (ISO, HACCP, Halal) and are trusted by meat processors and food manufacturers across Europe.

👉 Whether you need fine, medium, or coarse granulation, plain or seasoned varieties, we supply tailor-made solutions for your production line.

Contact us today to request samples, discuss your sourcing needs, or explore private label opportunities

poultry-coating-systems

Breadcrumb Blow-Off in Poultry Products 2026-01-13Seafood Processing Challenges

fish-fillet-coating-delamination-causes-fixes 2025-12-28Seafood Processing Challenges

tempura-vs-clear-coat-batter-shrimp-lines 2025-12-28Improving Consistency in Breaded Chicken, Nuggets & Tenders Through Modern Coating Systems...

Read MoreThe demand for breaded and coated seafood continues to rise across the UK and Northern Europe....

Read MoreAgrocanned’s Natural Colorants deliver clean-label, vibrant shades engineered for reliable...

Read MoreStandard Breadcrumbs: The Core Ingredient Behind Every Perfect Seafood Coating 1. Consistency...

Read MoreIn today’s global food manufacturing market, choosing the right breadcrumbs supplier is about...

Read MoreIn today’s fast-moving food industry, brands are constantly searching for new ways to deliver...

Read More